您的当前位置:

中铸首页

>> 案例展示

>>

客户案例

>>

1000mm砂箱尺寸造型机应用于井盖造型生产

您的当前位置:

中铸首页

>> 案例展示

>>

客户案例

>>

1000mm砂箱尺寸造型机应用于井盖造型生产

辽宁大连陈总于2019年年底采购中铸机械1000mm X 850mm 大型砂箱非标尺寸全自动造型机用于井盖井圈铸造造型生产,由于疫情影响,2020年4月份到中铸机械验收设备,2020年5月月底正式安装调试完毕开始投入使用,上图拍摄记录于中铸机械技术人员调试期间。造型机完成砂型造型后将砂型推送至升降机的底板小车上,再经升降机上的气缸推送底板小车往尾部传送。

由于场地的限制与客户要求重新利用环形线作为浇注及传送辅线,砂型经由底板小车传送后经过另外的气缸推送至环形线的平台小车上,经过不断的循环传送摆放后浇注冷却

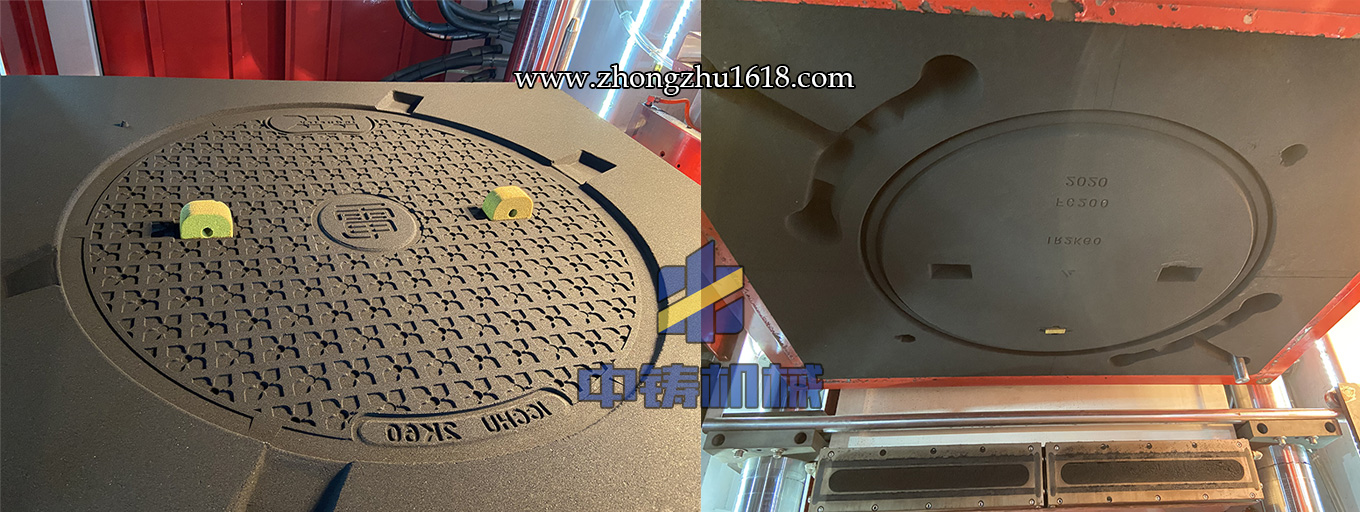

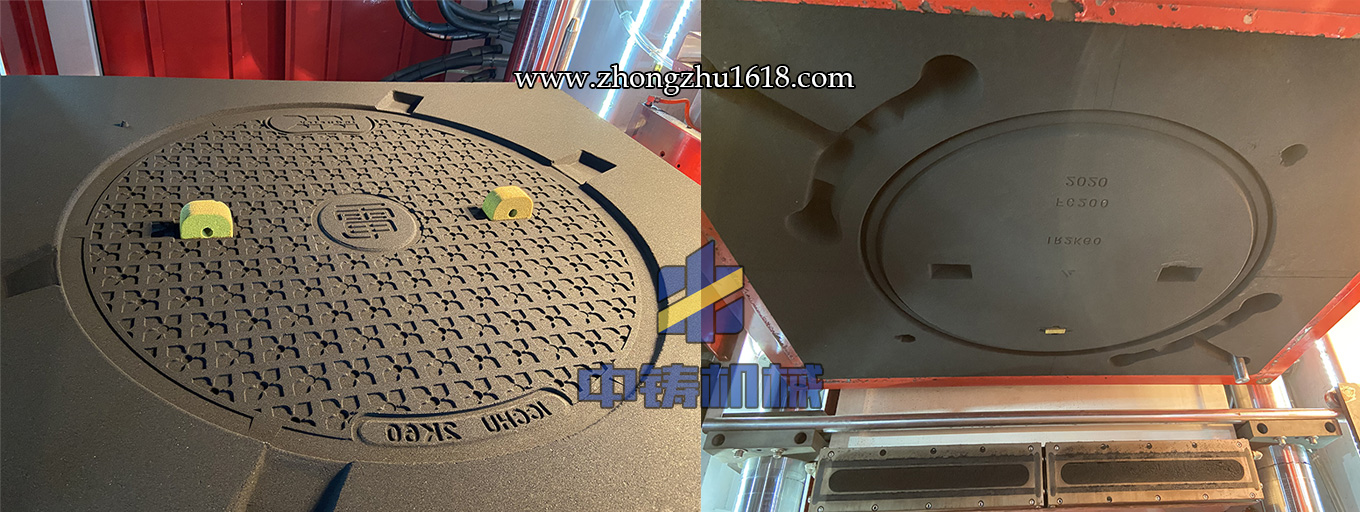

全自动造型机压实造型后的井盖造型效果图片(下砂箱图片和上砂箱图片)

经过造型机铸造造型生产出来的铸件产品效果图片,铸件将出口东南亚国家!

辽宁大连陈总于2019年年底采购中铸机械1000mm X 850mm 大型砂箱非标尺寸全自动造型机用于井盖井圈铸造造型生产,由于疫情影响,2020年4月份到中铸机械验收设备,2020年5月月底正式安装调试完毕开始投入使用,上图拍摄记录于中铸机械技术人员调试期间。造型机完成砂型造型后将砂型推送至升降机的底板小车上,再经升降机上的气缸推送底板小车往尾部传送。

由于场地的限制与客户要求重新利用环形线作为浇注及传送辅线,砂型经由底板小车传送后经过另外的气缸推送至环形线的平台小车上,经过不断的循环传送摆放后浇注冷却

全自动造型机压实造型后的井盖造型效果图片(下砂箱图片和上砂箱图片)

经过造型机铸造造型生产出来的铸件产品效果图片,铸件将出口东南亚国家!