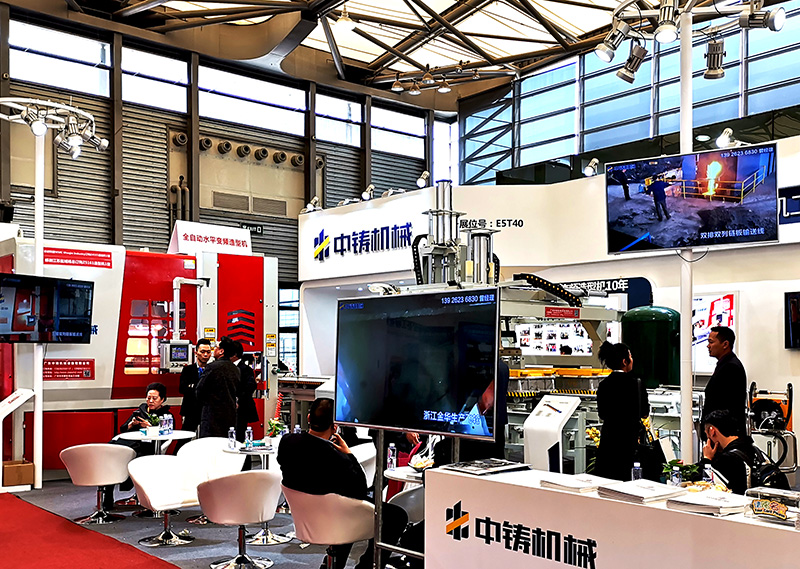

ZOOMZU Running VideoFoundry Molding Machines-Molding Line Video

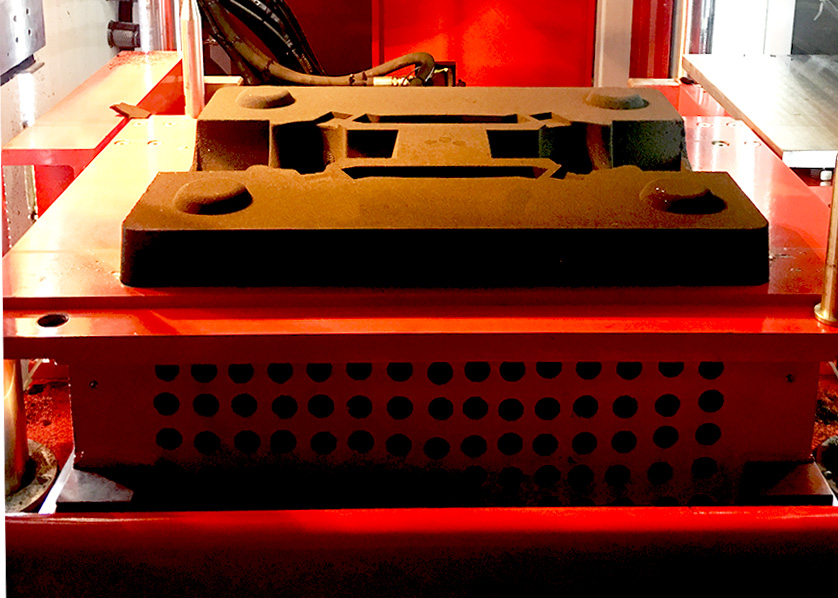

- Horizontal Automatic Molding Machines

- Top shot sand + Bottom shot sand Molding Machines

- Automatic Molding Line

-

MORE >

Equipment

Equipment

-

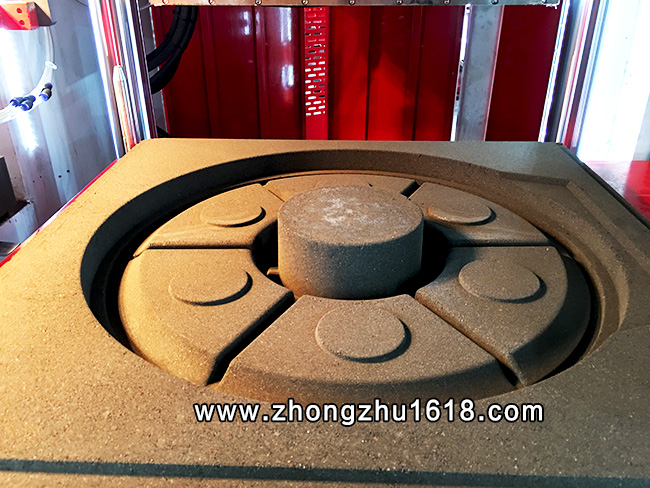

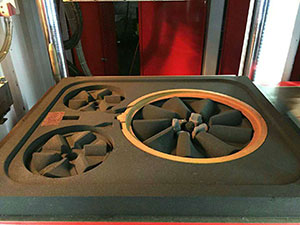

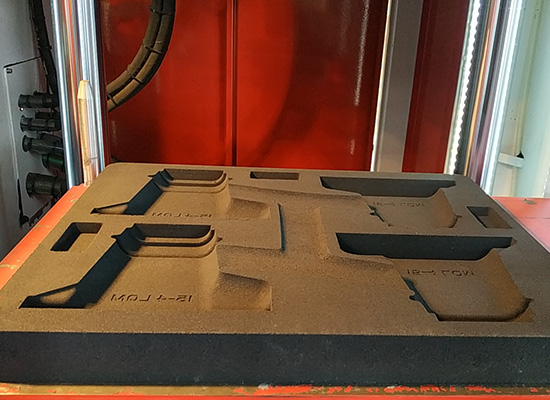

Automatic frequency conversion horizontal molding machine (710mm X 610mm)

Sand embryo size : 610*710*380mm (Length * width * height)

Modeling method: Pneumatic sand blasting + hydraulic compaction

Modeling speed: 36sec/mold (Excluding the time for placing mud core)

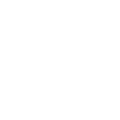

output voltage: AC220V ~ 380V(DC24V)

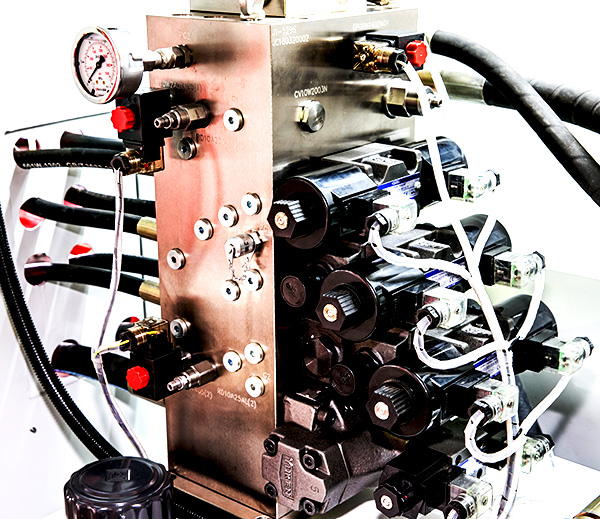

Motor power: 18.5KW

Sand weight: 230kg

Net weight of machine: 10500kg

Sand box Height: TOP sand box100--180mm Bottom sand box100--180mm (Adjustable)

-

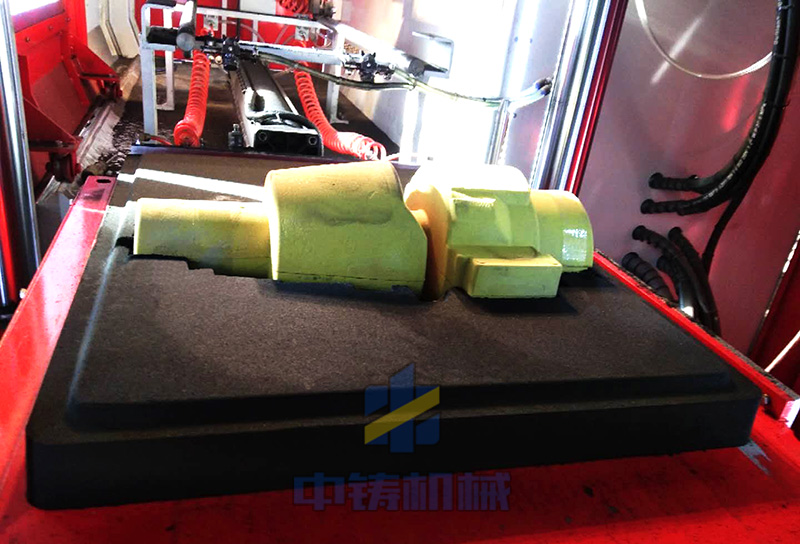

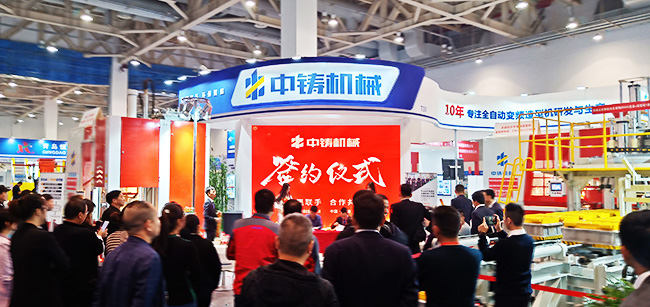

Top shot sand + Bottom shot sand molding machines (710mm X 610mm)

Sand embryo size : 420*520*300mm (Length * width * height)

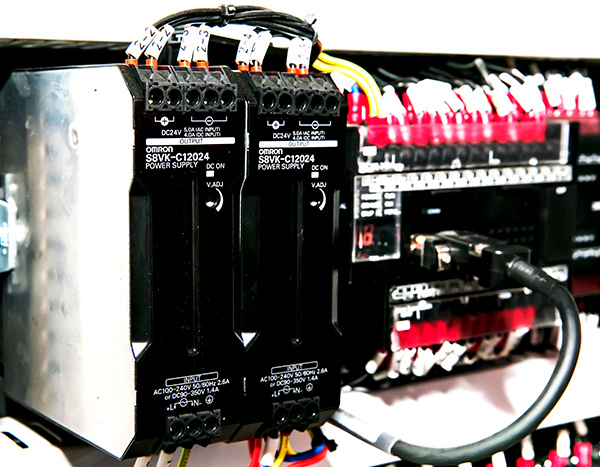

Modeling method: Pneumatic sand blasting + hydraulic compaction

Modeling speed: 38sec/mold (Excluding the time for placing mud core)

output voltage: AC220V ~ 380V(DC24V)

Motor power: 18.5KW

Sand weight: 250kg

Net weight of machine: 11500kg

Sand box Height: TOP sand box80--150mm Bottom sand box80--150mm (Adjustable)

Outline size: 4130*2441*4068mm(Length * width * height)

-

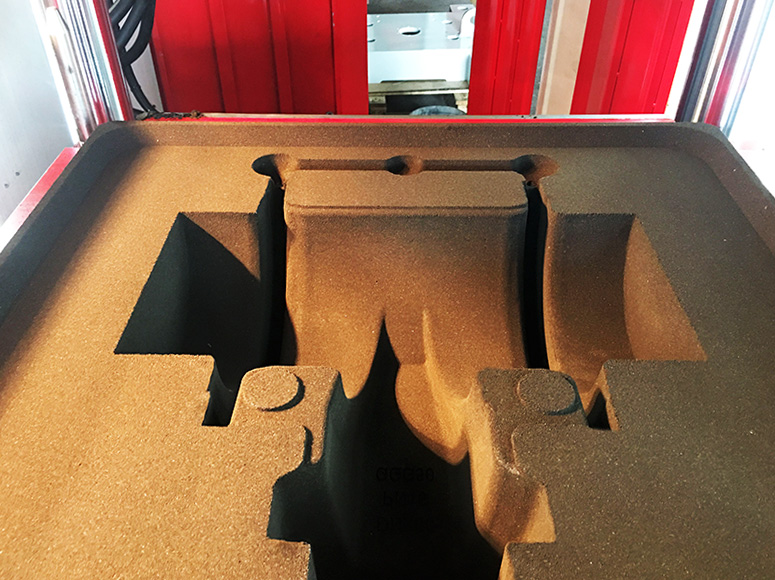

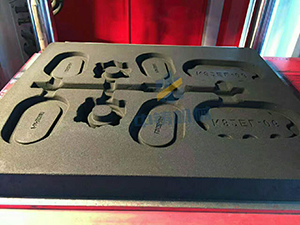

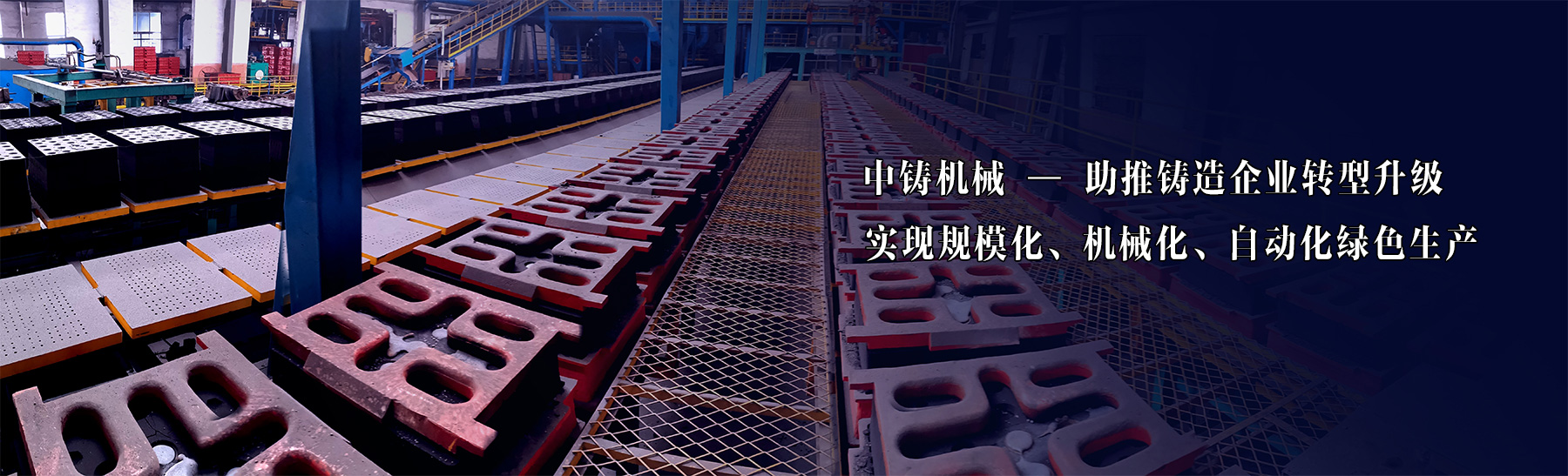

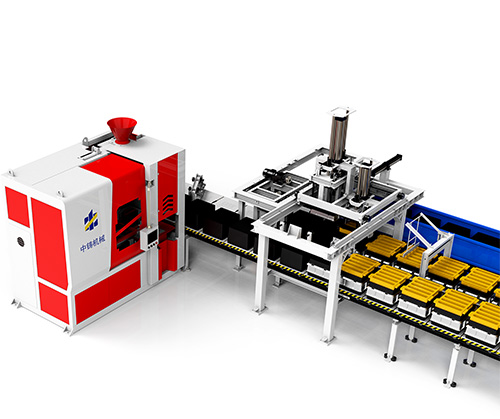

Automatic Molding Line

Station trolley: Material HT250.High frequency annealing

Sand box: QT450-10.Inner wall machining

Pressing iron: HT250,160KG-180KG.Underside processing

Hydraulic system: Siemens 11kw variable frequency motor.Yuken hydraulic oil pump

PLC:(OMRON)PLC;10 inch Omron touch screen

Manipulator pressing iron sleeve device: Cross cylinder;Lifting cylinder;Two sets of manipulator pressing iron sleeve box device;One set of transfer frame and one set of transfer vehicle;One set of lifting car;operating platform;Seats and solenoids;Tank chain;Internal wiring and piping;

Sanding mechanism: Siemens variable frequency 1.5KW motor,Weldment,high frequency annealed:Gantry CNC machining