—Focus on the research, development and production of full-automatic horizontal stripping molding machine!!

Your current location:

HOME

>> Case

>>

Case shows

>>

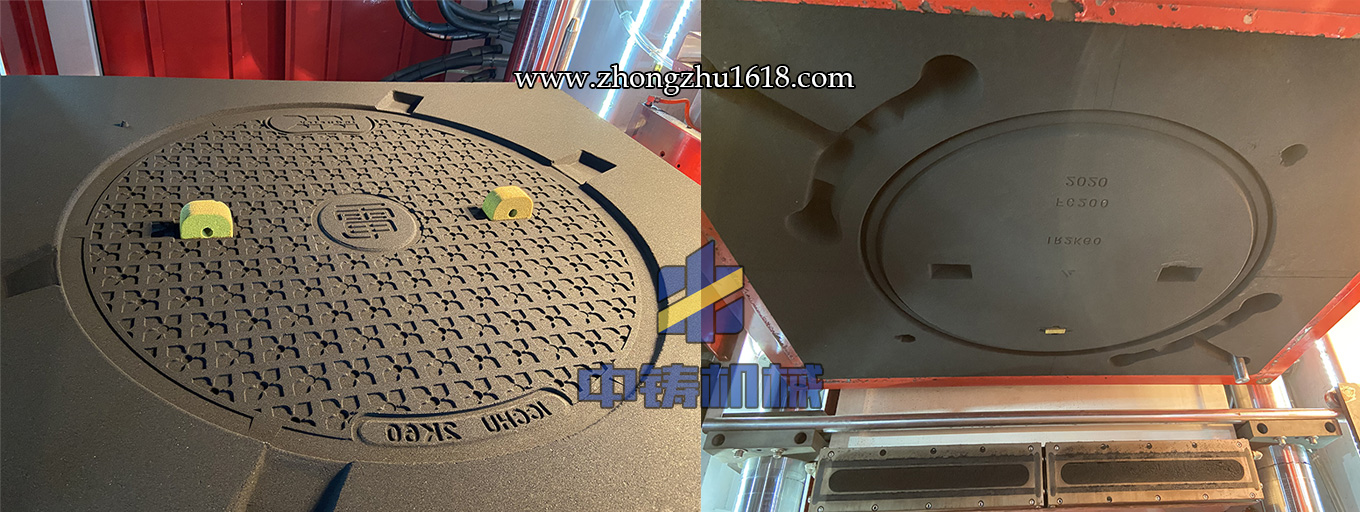

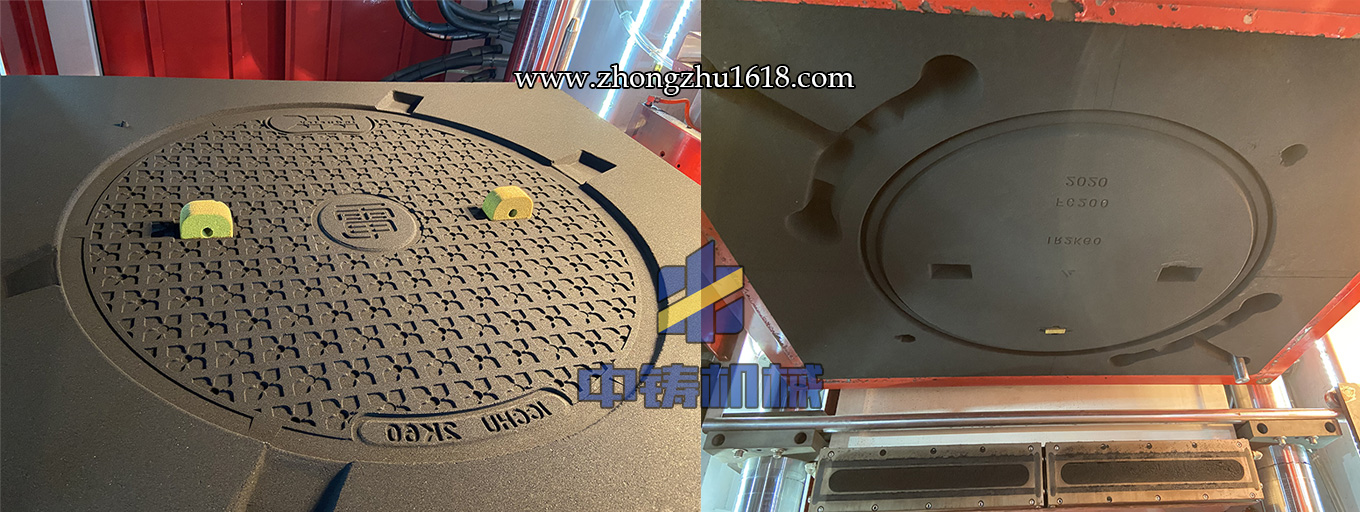

1000mm砂箱尺寸造型机应用于井盖造型生产

Your current location:

HOME

>> Case

>>

Case shows

>>

1000mm砂箱尺寸造型机应用于井盖造型生产

20191000mm X 850mm 2020420205

!

20191000mm X 850mm 2020420205

!

Long press QR codeAdd wechat friends

Long press QR codeAdd wechat friends

China zoomzu mechanical equipment Co., Ltd

Telephone:008613926238353

Contacts:Mr. Li

E-mail:470199755@qq.com

Address:Huadu District, Guangzhou City, Guangdong Province, China

Record number:粤ICP备16050083号

Website address:https://www.zhongzhu1618.com keywords:foundry molding machines foundry molding machines